Technology Overview

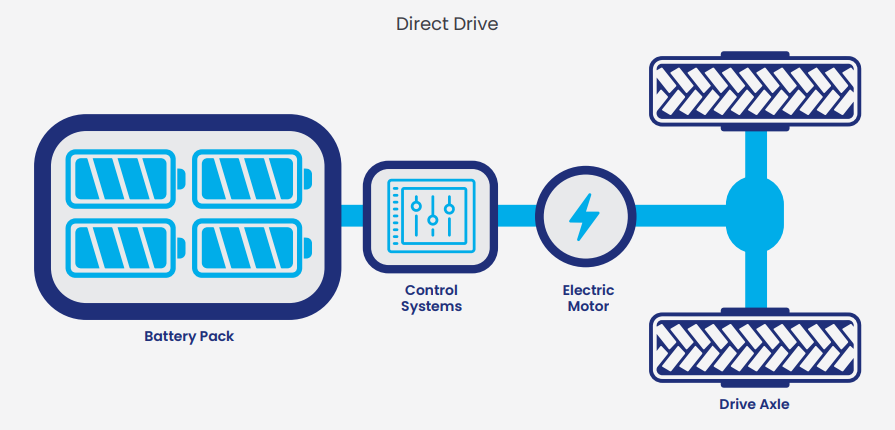

Battery Electric vehicles (BEVs) operate using an electric motor powered by an onboard battery for propulsion rather than a diesel internal combustion engine. Electricity from the grid is used to charge the battery via cable, overhead pantograph or inductive wireless chargers depending on charging strategy.

Battery electric buses are designed with regenerative braking, enabling a proportion of the energy that would otherwise have been lost when the vehicle is decelerating to be recovered back to the batteries, typically 20-30% of total daily energy consumption.

Battery electric buses are ideally suited for city centre routes and zero tailpipe emission operation. Most battery electric buses are charged overnight in a depot and some take advantage of opportunity or top-up charging in-service to extend their daily range.

GHG emissions associated with electricity production need to be taken into account when calculating the WTW GHG emissions of electric buses.

The WTW GHG emisison savings for battery electric buses using current UK grid electricity, certified under ZEB accreditation, range from 62% - 84% compared to an equivalent Euro VI diesel bus.

For further information on battery electric buses and infrastructure, please download the Zero Emission Bus Guide.

Download the Zero Emission Bus Guide

Vehicle Suppliers

- Alexander Dennis

-

Website Email

- BYD

-

Website Email

- Caetano

-

Website Email

- Equipmake

-

Website Email

- EvoBus (Daimler)

-

Website Email

- EVM Direct

-

Website Email

- Irizar e-Mobility

-

Website Email

- Mellor

-

Website Email

- Pelican Yutong

-

Website Email

- Switch Mobility

-

Website Email

- Scania

-

Website Email

- Volvo

-

Website Email

- Wrightbus

-

Website Email

Case Studies

-

Depot Charging / Overnight Charging

-

Case Study: Depot Based / Overnight Charging

Operator: Abellio, London

Fleet: 34 x Caetano e.City Gold

Infrastructure Provider: Zenobe Energy

Thirty-four Caetano e.City Gold electric buses were introduced during 2020 on the P5 (Nine Elms-Elephant and Castle) and C10 (Canada Water-Victoria) from Abellio London’s Walworth depot. At the end of 2021, the first EV double deck buses were introduced to the depot with a fleet of BYD/ADL Enviro400EV buses entering service on route 63, bringing the share of EV buses to over 35% of the depot’s allocated fleet.

Abellio London worked with EV fleet and battery storage specialist Zenobē to deliver the initial depot-based plug-in charging infrastructure at Walworth, later working with Siemens on the project for the double decker buses. The initial depot installation included a 1.2MW stationary battery-storage solution to help with the charging management.

The Zenobē battery supports the power requirements of the fleet, allowing Abellio to use a smaller grid connection. The stationary battery charges during the day while the electric buses are in service, and the stored energy charges them overnight. The battery’s energy can also be used during peak hours when energy from the grid is more expensive, reducing Abellio’s energy costs for charging the fleet.

-

Opportunity Charging

-

Case Study: Opportunity Charging

Operator: Harrogate Bus Company (Transdev)

Fleet: 8 x Volvo 7900E

Infrastructure Provider: ABB

In 2018, Harrogate Bus Company, part of Transdev Blazefield, introduced eight Volvo 7900E battery electric buses to the town’s bus network with the support of £2.25m of UK Government Low Emission Bus funding.

The buses adopt an ‘opportunity charging’ strategy to ensure each ‘Harrogate Electrics’ bus can efficiently and reliably perform throughout a full day of service without interruption. Using pantograph charging systems installed at Harrogate Bus Station, top-up charging takes place during layover periods in service while the vehicle stands. This top-up charge supplements overnight charging at the company’s Starbeck depot, which is required to balance the battery packs.

The charging equipment and substation installed at the bus station are supplied by ABB, and utilise the ‘pantograph-down’ methodology which features a pantograph extending down from an overhead mast to connect with charging rails mounted on the roof of the bus.

The system charges vehicles at up to 300kW, allowing each bus to be charged in less than 10 minutes, eliminating the need to wait for long charging periods during service. The units are compatible with the OppCharge interface, enabling compatibility with potential future expansion using other vehicle models.